Wood Chip boilers

Wood chip boilers operate similarly to fossil fuel boilers. When heat is needed, they automatically ignite, feed fuel to the fire, and shut off as required. Their automated functionality makes them an excellent alternative for those seeking a cost-effective and environmentally friendly option compared to traditional oil, LPG, or electric heating, while ensuring high comfort levels.

Wood chip boilers are typically more suitable for larger domestic and commercial applications, where the additional fuel savings can offset the slightly higher initial capital costs and the greater space and input required for fuel storage. Some models designed for wood chips are also capable of burning wood pellets, providing greater versatility in fuel options.

Benefits of a chip burning boiler;

- Fully automatic control and feed systems

- Automatic ignition and cleaning

- Option of automatic weather compensation

- Eligible for both the Domestic and Non- Domestic Renewable Heat Incentive Schemes

- Wood chips offer an automated heating solution at a lower cost than wood pellets

- Can utilise own/local woodland to provide fuel

- Significant fuel savings over oil, LPG and electricity

- Lambda controllers ensure high real-life efficiencies up to 93%

- Designed for long operational life

Smaller domestic properties and light commercial installations |

Compact 30-45-50-65-95 rangeCommercially engineered wood chip boiler sized for domestic and commercial applications. Compact 30-45Well insulated 4-6 bedroom house with larger than average hot water demand and/or swimming pool. Small to medium commercial application. Compact 45-50Medium to large country property or large urban house. Small school or rest home, manufacturing process with heat requirement or space heating. Compact 65Medium to large country property or large urban house. Small school, rest space heating. Compact 80-95Large country property or large urban house. Medium rural primary school, rest home, manufacturing process with heat requirement or space heating.

|

Larger domestic properties and commercial installations |

Compact 100-115-150-200 rangeCommercially constructed wood chip boiler for heavy load applications with continuous long operation periods or regular stop and start applications. As a guide the Compact 100-200 range of wood chip boilers might suit: Large country or urban houses. Medium to large hotels, rest homes and medical care. Process applications such as wood fuel drying, food, animal, chicken production. M Series 300-350-400-500 rangeIndustrially designed and built wood chip boiler for heavy work loads with nominal working hours of 4,000 hours per year. Larger shopping centres or showroom properties, car, supermarket, shopping centres and out of town stores. District heating of housing estates, industrial complexes. |

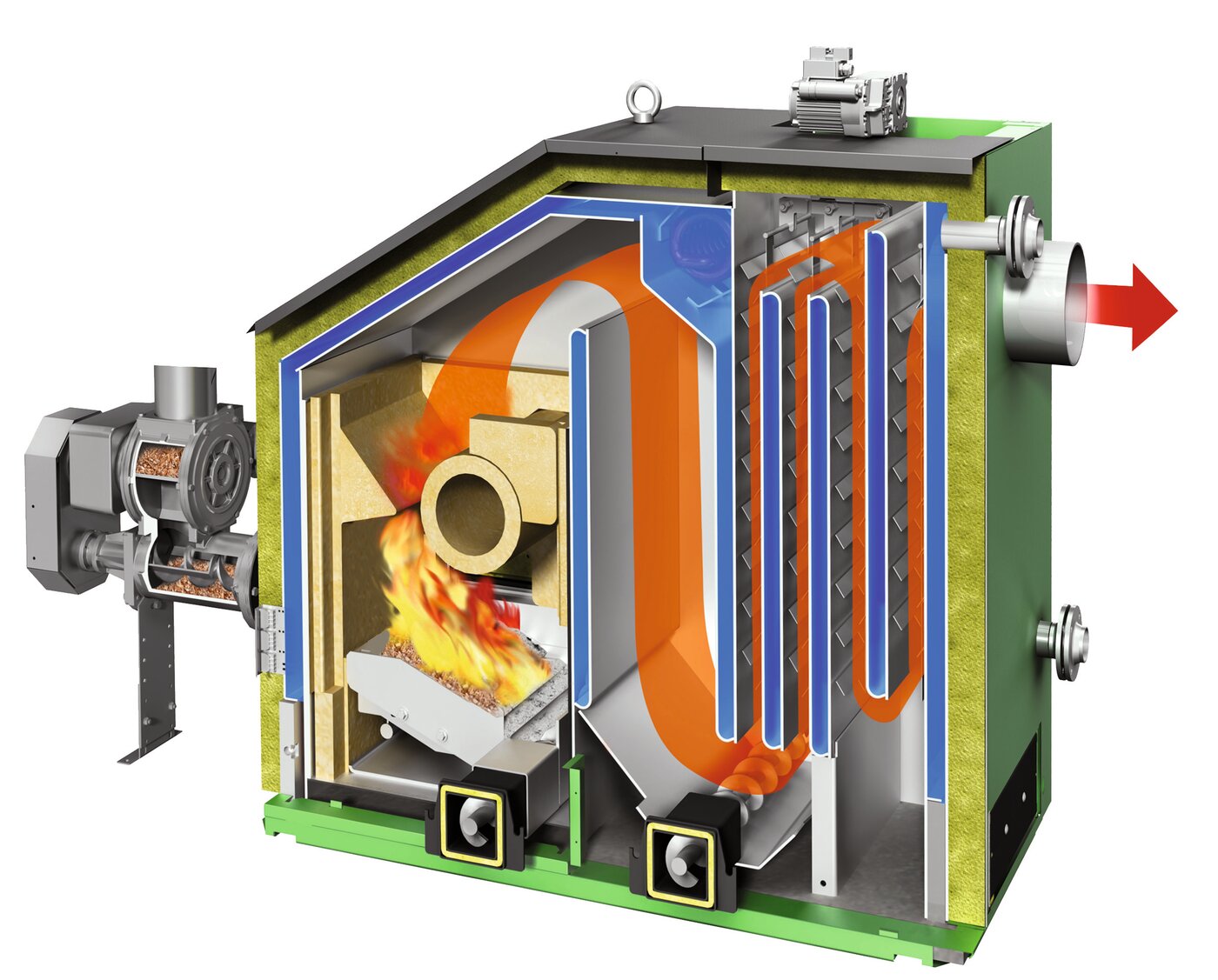

Combustion Control

Wood chip boilers require automatic combustion control to adjust to the varying nature of wood chip as a fuel. The most advanced and efficient boilers encompass a lambda sensor to adjust the primary and secondary air for the highest possible efficiencies. The controller ensures the precise mix of fuel, primary air, and secondary air at all stages of combustion to ensure efficiencies of up to 93%.

Fuel Storage

Wood chip boilers require larger fuel stores than the equivalent sized wood pellet system. Fuel stores should be sized so as to allow the boiler to run for a minimum of approximately 4 weeks in the coldest weather without the need to replenish the store. A number of methods can be used to fill the fuel store and are dependent upon individual sites and equipment available.

Perfectly regulated with the HDG Control

The new HDG Control is the intelligent control centre for your entire heating system. Whether on the large touchscreen on the boiler or via the app: With HDG Control, you always have absolute control over your heating system.

- Control of combustion and output

- Control of external heat sources

- Integration of solar thermal systems, accumulators, heating circuits, mains pumps

- Domestic hot water preparation, etc.

- On request: Full web access and app for iOS and Android